13 April 2020

This page details various bag sizes and why the bag supports in any design should be adjustable. The key is to find points on each bag that provide support and lateral constraint, but do allow the bag to flex as it is compressed. The bag should be centered laterally and vertically between the grippers. The table below gives dimensions at the contact points and the center of the bag. We place the bag with the bottom towards the motor and head, with patient valving, overhanging. Remember, this valving must be extended as described in Plumbing.

For practical purposes, spacing the bag mounts 21 cm apart should fit most bags, but the mounts must have vertical adjustability.

| bag | distance | bottom ø | top ø | center ø |

| Ambu Spur II & Adult Silicon | 21 | 61 | 29 | 129 |

| Care Fusion | 21 | 54.5 | 50 | 134 |

| Laerdal The Bag | 21 | na | 40 | 139 |

| Portex | 20.5 | 61.5 | 37 | 131 |

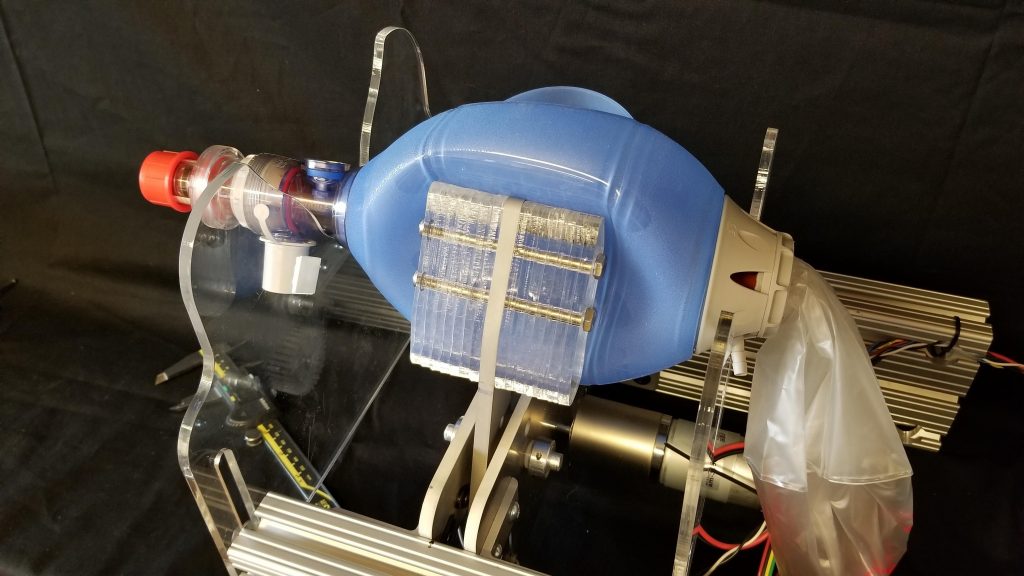

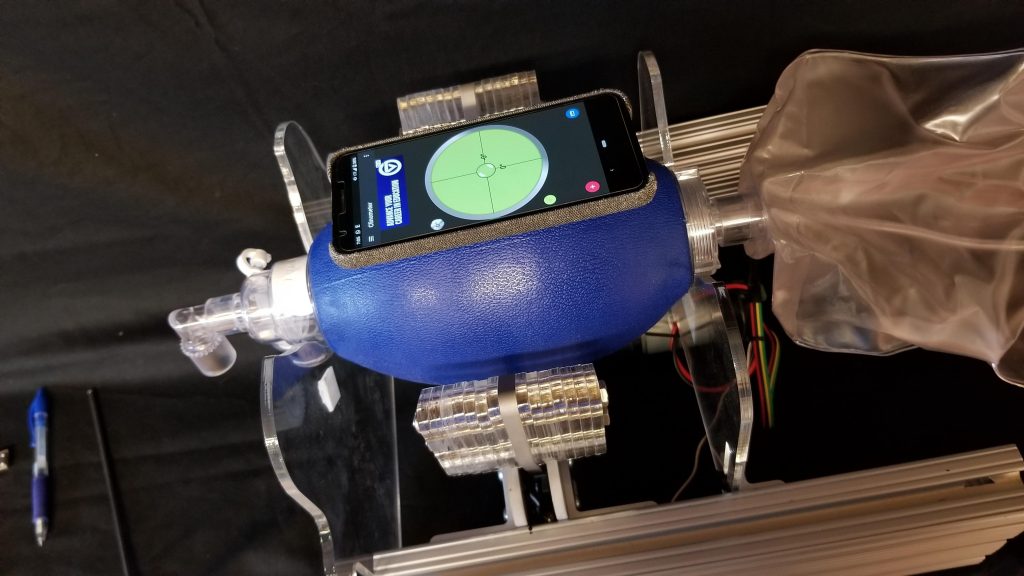

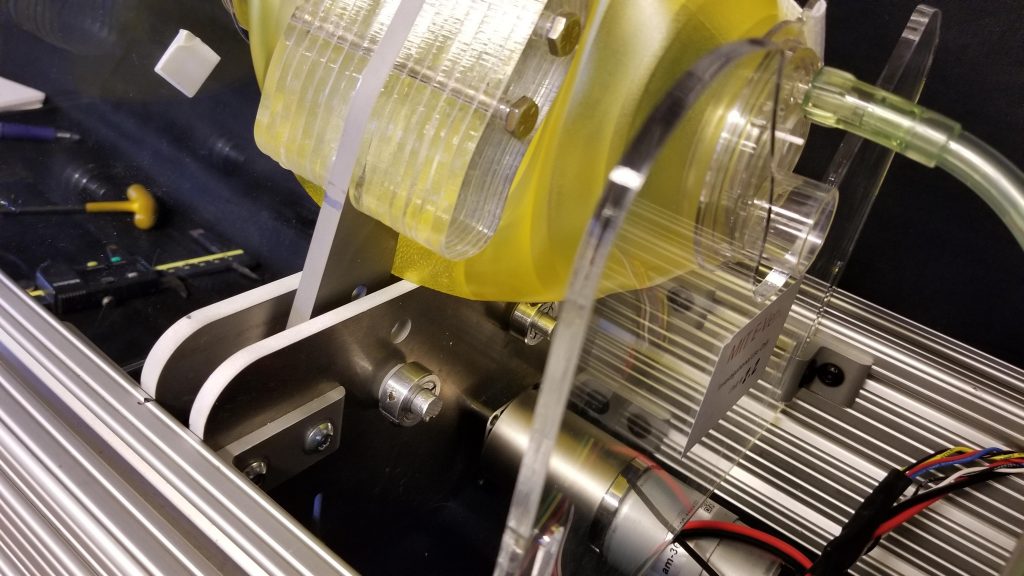

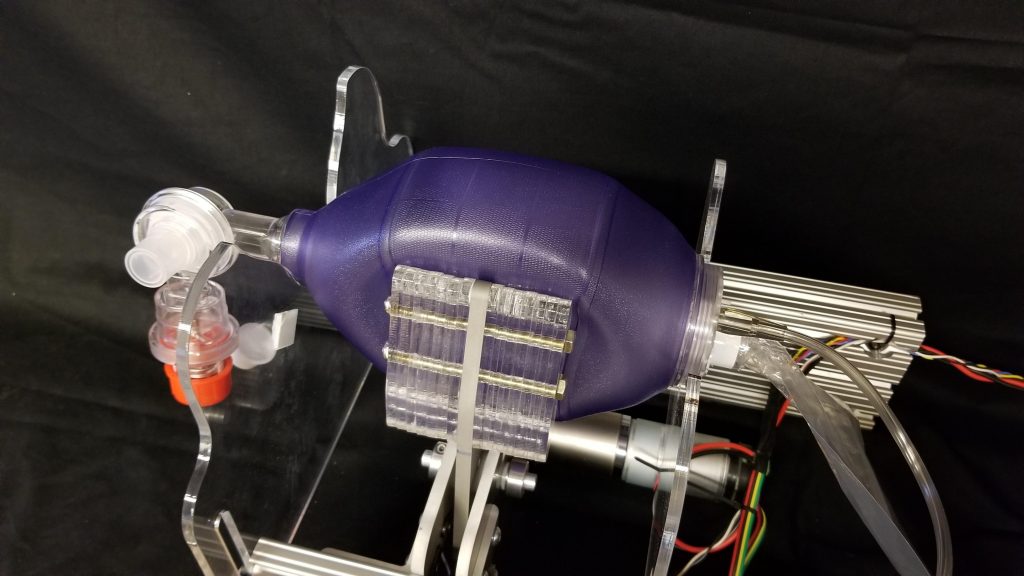

Below are pictures of each bag type that we measured, shown in Version 2:

Note: In Version 3 we added hooks and an elastic to prevent unintended bag removal.

This is great information – thank you. Are any controller adjustments necessary to accommodate for differences in bag stiffness, or do pump air pressure sensors provide necessary information?

A good controller should handle this, but you will want to calibrate the system for a specific bag size in terms of volume delivered.

Gear on motor shaft will create radial load. Hope the bearings of the planetary gear motor are suitable to handle the bending moment.

We are conducting destructive testing …

Also, any consideration to using thin quick release fasteners, such as velcro straps, on the plexiglass ends to secure the bag so it wouldn’t be accidentally moved or dislodged? It might also solve the Portex bag problem, and the bag could still be quickly removed for manual use in case of an error or malfunction.

Yes, hooks for elastics have been added to Version 3.

The fixed ends may be more of a problem than a feature. If the bag is allowed to move, the difference in size will not be an issue. It would just be a matter of software to calculate tidal volume.

Hi Thiago,

please can you tell me how you calculate tidal volume?

Tidal Volume (TV) = inspiratory flow x inspiratory time

Minute ventilation = VE = (TV x respiratory rate)

TV = minute ventilation / respiratory rate

Tidal volume is a set parameter in volume controlled ventilation. The tidal volume that is set by the clinician may be determined through the consideration of multiple factors, such as the patient’s body weight, physiologic state of the patient, plateau pressure, desired minute volume, etc. More information can be found under the “clinical” page of the website (link: https://e-vent.mit.edu/clinical/).

Hello, excellent work you are doing, my congratulations. A consultation, where the contact point is located, measured in the hand, between the hand and the bag?

Good morning team, You had mentioned US Air Project printing the valve manifold for use, do you by chance have the file? Did they make you one? We have a team of engineers working through the production of these units and outside all the information readily available, this is one piece of puzzle we are hoping to not recreate. So far we have PCB design done, materials en route, and CNC/3D Printing resources lined out. Excited to start building.

Good day Team.

Any know what is the material of this bag? PVC, Butile, SBR?

Hello, the ones I know are silicone or SEBS

Thanks Andres, Butilo-Estirene.

I belive that in my company, we can manufacturing this.

Nice..

There is always a chance that “Ambu” bags and such will be in short supply also, various labs are using same bags with different ways to compress it, why not use a bellows based machine, where the bellows can be made locally by locally made materials (leather, vinyl, rubber etc).

Bhavesh – i am experimenting with a section of a flexible 4inch hose driven by stepper motor or other means; see if this may work. https://www.walmart.com/ip/HOSE-VINYL-FLEXIBLE-4INX8FT

Jorge Lange

Any one knows the coding for system? Or complete procedure step by step to build this ventilator..Indonesia very needs this ventilator… Send to my Whatsapp = +6281327041497 or my email kim_yus2003@yahoo.com

and we can joint..

Can you add information on the size of the pressure sensor connection (diameter of the sensing port)?

While you wait, please see this note.

https://www.vent.me/post/i-farm-honeywell-trustability-pressure-sensors

In the above URL, see this note:

“Note: These sensors all come with a 2mm hole nipple. From what I’ve read, most tubing around a patient is 5mm to 7mm, so you’ll need an adapter.”

While you wait, please see this note.

https://www.vent.me/post/i-farm-honeywell-trustability-pressure-sensors

In the above URL, see this note:

“Note: These sensors all come with a 2mm hole nipple. From what I’ve read, most tubing around a patient is 5mm to 7mm, so you’ll need an adapter.”

I think the distance is 210mm (or 205), not 21.

I have access to a large tier 1 supplier of injection molded parts and metal stamping. The owner and CEO is willing to have his mold shop and his plastics company make anything necessary. He is not looking for startup money or profits. He would like to see a device sold for under $1000.00 dollars and that is not a typo. They can produce thousands of parts daily. He has had the best 4 years of his companies history and wants to give back to America.

In India, a group of doctors are against using this design of ventilator with bag. They can be convinced if it has been deployed somewhere in US or other countries.Can you please let us know what is the current status of testing, certification and deployment at Cambridge or other locations?

Present system is bi-directional system and motor need to be reversed for inspiration and expiration cycle. Reversing motor for days is not good for motor controller and will have reliability issue. Why can’t one direction motor operation can be used with cranking wheel or Cam?

did anyone have 3D models of different kind of Ambu bags?

I am going to build some accessories to suit the mounting. See if anyone can help?

From download 3D model, the bag holder distance is around 300mm. And the bag distance is 210mm. Do I have misunderstanding for the dimension? Does anyone have a detail dim spec for the bag? I am going to design the bag holder, wish someone can help me to get the about dim spec. Thanks!

How do you prevent the bag ends from coming out of the holders when it is compressed.

As the bags are compressed, the two ends move together along its axis, do you account for this somehow?

Please refer to the “Bench Testing” page on the E-Vent website (link: https://e-vent.mit.edu/testing-results/bench-testing/). Here you will find the results of durability testing trials where the E-Vent was tested for 24 hours with no securement other than being placed in the mounts in order to determine it would move. After the 24 hour test, the bag had not changed position, indicating it experienced no torque that would cause it to move during operation. More detailed information regarding this test and the other tests that were performed can be found on the “Bench Testing” page. Also, as you can see in the picture of E-Vent Version 3 on the homepage, we used an elastic band to hold the manual resuscitator in place.

How long the AMBU bag can be compressed(operational) in terms of hours ? or any any interval of time it has to be replaced ?

This will likely vary based on the patient’s health status and subsequently the machine settings. Because this is a volume control machine, the applied pressure is varying. Therefore, different pressure requirements implemented on the Ambu bag will affect the longevity of the bag. For example, higher pressures will be required for an obese patient compared to one with a normal BMI.

Additionally, this machine allows for different bag sizes and brands, which will demonstrate variations in Ambu lifespan. Since this machine utilizes the bags in a different manner than its on-label use, previous data examining the Ambu bag longevity is not entirely applicable in this situation. Patients with acute respiratory distress, like COVID-19 patients, have lower compliance lungs compared to the average person. Therefore, higher pressure may be required within the bag to deliver a desired tidal volume. The longevity of the bags may be different than their longevity observed in other emergency situations, like cardiopulmonary arrest.

Bench testing done used the Ambu Spur II. The bag was in good condition after a 24 hour wear test. However, there were shortcomings to this test, as the bag did not experience the resistance that would occur when delivering oxygen to a low compliance lung, as in ARDS. Also, because this is a disposable bag, the longevity is likely less than one used in a hospital setting, like the Ambu Oval Silicone Resuscitator. One technique that could also increase the lifespan of the bag is to rotate it periodically in order to more evenly distribute the stresses. Additional information can be found on the “Bench Testing” page (Link: https://e-vent.mit.edu/testing-results/bench-testing/) regarding the various testing and troubleshooting performed with the Ambu bag.

hey, can anyone tell me? if I can do any flow analysis on Ambu Bag or any other Ansys simulation. if yes, then please share the information regarding this.