Updated 13 April 2020

This page provides an estimate of the maximum power required by a motor used to compress an Ambu bag using a double gripper design, actuated from the bottom. Different designs, with other actuation methods, will change motor specifications, but the power should stay approximately the same.

Caution: Many designs circulating on the internet significantly underestimate the pressures needed to inflate a subject’s lungs. There is a reason why the diaphragm is a large muscle. However, adding more power without great care is equally dangerous. In addition, COVID-19 compromised patients may require more aggressive motion profiles, i.e. short, quick breaths and longer exhalation times. In specific, clinicians are reporting I:E ratios of 1:4 in COVID-19 patients. (Our estimates use 1:4.)

Theoretical Power Requirement

Independent of the mechanical design of the gripper, the required power output can be computed from the worst-case values of the following variables:

- Maximum pressure at airway: Pairway,max = 40 cm H2O (pop off cracking pressure)

- Maximum respiration rate: RRmax = 40 bpm

- Minimum inhale/exhale ratio of 1:4: IEratio, min = 4

- Maximum volume output: Vmax = 800 cm3

That is, in the worst case the device needs to squeeze of air at a pressure of 40 cm H2O, in a 0.3 second (tinhale = 60 sec / RRmax / (1 + IEratio, min)).

The volumetric flow rate needed in the worst-case (peak) scenario is, then:

Qairway = Vmax / tinhale = 0.0027 m3/s

The power output (in the form of pressurized volume flow in the airway) is:

Powerairway = Pairway,max Qairway = 10.46 W

However, some of the power used for squeezing the bag is lost (bag deformation, friction, etc.) and let’s estimate that 50% is converted to pressurized volume flow. Taking this efficiency into account, the power required at the gripper is:

Powergripper = 2 Powerairway = 20.92 W

The actual power needed from the motor will be higher, how much higher depends on the mechanical and electrical designs. Assuming half the power output of the motor is lost to mechanical and electrical inefficiencies (gears, thermal dissipiation, etc.), the power output required from the motor is given by:

Powermotor = 2 Powergripper = 41.84 W

Power requirement for 2-finger design

This is an alternative approach to calculating power.

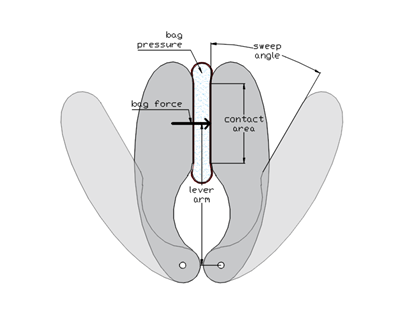

The following is an illustration of a 2-finger gripper design:

A more direct approach can be used for this design provided the following quantities can be measured:

- Finger-bag contact area

- Finger lever arm length

- Sweep angle

For one particular prototype, we have:

- Finger-bag max contact area: Abag = 90 mm ✕ 115mm

- Finger lever arm length: lfinger = 12 cm

- Sweep angle: αsweep = 30°

The maximum force of the bag on one finger (when fully squeezed) is, using the same 50% pressure transmission efficiency as before:

Ffinger = 2 Abag Pairway,max = 81.199 N

The maximum torque needed on each finger is then:

?finger = Ffinger lfinger = 9.74 N.m

Now we can compute the power required for the two-finger gripper using the sweep angular rate ( in 0.3 second):

Pgripper = 2 ✕ ?finger wfinger = 34.01 W

The total power for the motor (assuming a single motor) when additionally applying the same 50% motor and gearbox efficiency, we get:

Pmotor = 2 ✕ Pgripper = 68.03 W ~70 W.

Benchtop Validation

During testing of a 2-finger gripper design, Emergency Ventilator Unit 3.1, equipped with an Andy Mark motor am-3656 (188:1 gearbox) we observed under normal operations a peak current of about 5 A at 12V or 60 W.

Recommendation Minimums

The minimum motor power is approximately 70 W. Therefore, a power supply at 12 V should be specified with a minimum of a 5.8 (~6 A) supply.

Caution: The torque required of the motor will be a function of whether the arms are driven directly or with a driving pinion. It is essential to consult your motor curves and apply a safety factor.

Recent Comments